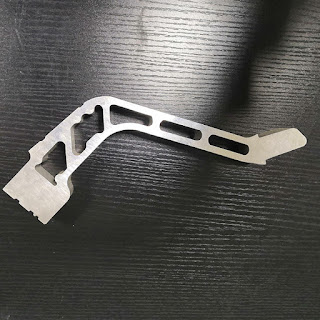

Aluminum extrusion

- A process through which aluminum is forced into a custom made die and results

in a consistent cross-section that utilizes all the buildings of the metal.

Aluminum is utilized in several markets as it is among the most versatile and

easily available metals in the world. The benefits of using aluminum to develop

products prevail - it is lightweight yet really solid and long-lasting, it is

an outstanding thermal conductor-- both to dissipate and show heat, it can

carry out electricity, it is conveniently machinable as well as flexible,

essentially impossible to wear away and sets you back extremely reduced! All

these facets reveal the merits of aluminum both for the producer as well as the

consumer.

Aluminum extrusion has changed the lightweight aluminum market for many factors

It has removed the

restraints that held many designs back. Making use of a die suggests that any

type of aluminum shape can be produced to the developer's exact specs without

any loss of consistent cross-section as well as tension in the steel. The

passes away used in aluminum extrusion are cheap to make and also they have a

lengthy life, which makes them very affordable for the supplier. Utilizing a

die additionally suggests that there is no additional machining involved in the

procedure which can cause extra waste and also prices, similarly, there is no

need for manufacture with welding. Welding can develop high additional costs

that do not reduce dramatically with the recreation of the same component, not

only does this take extra labor yet also develops more expense as the welding

jigs utilized are commonly more expensive than the aluminum extrusion pass

away.

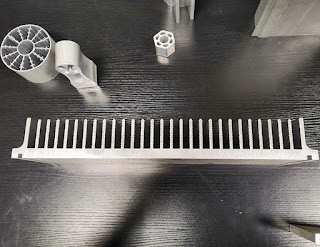

Aluminum extrusion

has additional benefits to the supplier that assist solve the issues of extra

prices if making use of sand or long-term mold spreading. The primary one

starts that lightweight aluminum extrusion gets rid of the requirement for

completing after it is taken from the die. Utilizing other approaches produces

a rough coating that needs fining sand and also polishing before it can be

classified as completed. Aluminum extrusion produces a very smooth surface that

does not require any more complete.

Lightweight

aluminum extrusion is without a doubt one of the most affordable and also

trustworthy ways of producing any kind of layout form making use of aluminum

without needing to compromise on anything. It is a huge action for the sector

and it suggests that more complicated aluminum styles can be produced easily

and to the exact specs of the designer. Formerly these several layouts might

not be produced because of the restraints of the production procedure. Today

this notion is unheard of because of lightweight aluminum extrusion and

everything from automobile parts to tubes can be custom made effortlessly and

also lowered prices.

If you are looking

for a cutting-edge firm that utilizes the very newest aluminum extrusion

processes to satisfy their customer's requirements visit www.eps-aluminum.com

where you can see what lightweight aluminum extrusion can do for you and your organization.

Aluminum extrusion implies that an organization no longer needs to be

restricted by what the standard techniques of producing lightweight aluminum

offered them with, currently, the only restrictions are a designer's

imagination.

No comments:

Post a Comment