A couple of decades ago if you heard the word "heat sink” you might be

thinking of a gigantic fan or a rather grotesque cooling

system. However, today the reality is different. Today's heat sinks

are much more sophisticated than their predecessors. Next, we tell you the

difference between the aluminum heat sink and other heat sinks.

For this article, we will only

emphasize aluminum and copper heat sinks, due to their efficiency and

versatility in different types of household appliances, computers, servers,

industrial machinery, etc.

What is a

Heat sink?

To start with, it is essential to answer the following question: “What is a heat sink?” Well, in

simple words, a heat sink is

“an additional element that is added to certain electronic devices to keep

their internal temperatures stable”.

In this order of ideas, there may be several accessories that meet the

previous definition. Usually, fans are perhaps the heat sinks most famous. However,

its efficiency has been questionable for many years, since the new electronic devices are increasingly

sophisticated and advanced in terms of their level of processing, making

them easier to heat.

Today, the definition of

heat sinks is much more complex than before. As we mentioned

before, today's electronic devices have great processing power. Besides,

said processing power is concentrated, mainly, in really small microchips

(microprocessors), so the heat is concentrated in that area with great ease.

Finally, the heat

sink works as a heat

conductor, which transmits

heat from a certain area to the surrounding atmosphere. The most

efficient at present are copper or

aluminum heat sinks. These elements have properties that allow you to conduct

heat through its surface, to later dissipate them, with great ease.

Copper or aluminum heat

sink...? Which is the best and why?

Both Copper and Aluminum have great qualities

for conduction and, later, heat dissipation. Both work

perfectly and can be used in different alloys and types of structure to enhance

their qualities. However, certain technical differences can be

established between the two best thermal conductors par

excellence: copper and aluminum.

In the following table, we will establish a comparison between aluminum and copper, we will analyze its

thermal conductivity, density, and price per Ton in US $:

Material

|

Thermal Conductivity

[W / (m * k)]

|

Density

(g / cm ^ 3)

|

Price per Ton

( US $)

|

Aluminum

|

205

|

2.7

|

1,882.00

|

Copper

|

385

|

8.96

|

6,326.50

|

Based on the previous table we can establish the following statements:

- Copper is the second-best element in thermal

conduction capacity, outperforming

aluminum by 53%. However, the price of aluminum per ton is more than 3 times cheaper than that of copper.

- The

density of aluminum is 3 times less than that of copper. For this reason,

and for its cheaper price, aluminum is the preferred material in terms of heat dissipation.

What are the best aluminum heat

sink manufacturers?

The best manufacturer, regardless of the product they offer, is the one

that knows how to take full advantage of the qualities and advantages of their

products and, subsequently, offer them effectively to their customers. In

this order of ideas, a good manufacturer of aluminum heat sink must know how to take full advantage of the qualities of this material

and adapt them according to the needs of their customers.

Importantly, globalization and the

increase in the world population have greatly accelerated the technological race,

and with it the production of new and more efficient heat sinks.

As aluminum heat sinks are the

preferred option by manufacturers and with so many of them currently, we find

it essential to make our recommendation: EPS Aluminum.

EPS Aluminum

The successful company EPS Aluminum has recognized, from its

beginnings, the versatility of

aluminum as a material. For this reason, they have

specialized, over the years, in all kinds of aluminum products such as aluminum

profile for buildings and decoration, extrusion dies, extrusion tooling,

aluminum frames for solar panels, and obviously, aluminum heat sinks.

As you can already imagine, we will place a special emphasis on aluminum heat sinks over the other aluminum products that EPS Aluminum offers.

Aluminum heat sink is more necessary than you think

Firstly, heat dissipation

is not just about electronic devices like computers and cell

phones, it isn't at all. Manufacturers of household appliances, specialized

electronic devices (robotics), and other industrial equipment also use aluminum heat sinks inside. Aluminum's

versatility and good thermal conductivity make it a favorite with many.

Material is not the only important thing,

designing a correct structure is also important

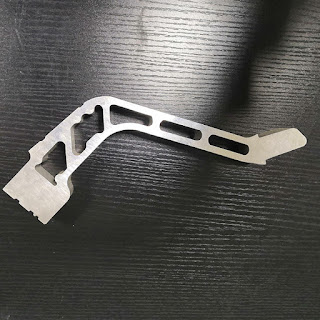

Secondly, to successfully dissipate heat, it is necessary to establish

a custom aluminum heat sink, that is, to develop a

structure that allows the correct removal of heat from a given surface through

thermal conduction.

Each electronic equipment or device, and even industrial machinery,

requires complex custom aluminum heat sinks, which must have a unique structure that adapts to the surface and shape

of the device from which you want to remove heat.

If you bring us a specific heat sink

design, EPS Aluminum makes it for you.

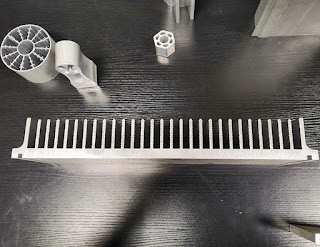

Thirdly, EPS Aluminum aims to become one of the

best aluminum heat sink

manufacturers in China. For this reason, it offers its clients the possibility of developing

customized, highly complex heat sinks for them, according to the requirements

of their clients and their previous design.

If you didn't have a concept of aluminum heat

sink before, you can check out the EPS site for aluminum heat sink.

Finally, EPS Aluminum owns the stock of its website to more than 15 different models of aluminum heat sinks. Every one of these heat

sink models has the same quality: to dissipate heat

from a certain area through thermal conduction. However, the application

of this quality may be different depending on the surface of the device to

which it is applied.