There are several options for you if you

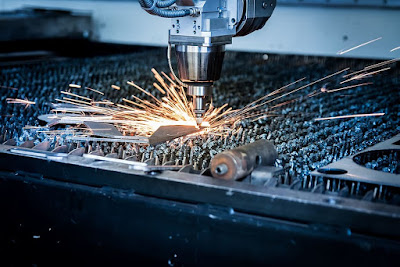

want to automate the robotic welding process in your shop. This reduces the

number of injuries in the facility and at the same time makes it more

effective. Although the robotic systems integrator will choose which of the

equipment is needed to automate the welding, you should verse yourself with the

options. This makes the process easier and quicker and at the same time gives

you the best system for your application.

In this brief, we are guiding you on all

the considerations for Robotic Welding Equipment and accessories. Verily, there

are few considerations to digest when automating the welding process.

Work needs

The types of works you will be performing and most importantly the types of objects that you will be welding matter a lot in the selection stage. The fact is each of the robotic welding processes work well for different objects. You can choose MIG robotic welding process if you work frequently with thicker pieces. If otherwise, then you can consider the TIG welding process.

New or Used Robotic Welders?

You also have to make your mind whether you

need new or used robotic welders. In most shops, you are very likely to find

shiniest and newest machinery but there’s no problem with going for a cheaper

second-hand robotic welder. The used welding equipment

is less expensive and the issues with them are already known. The other benefit

of used robotic welding

equipment is that they can be shipped on order.

It can be difficult to decide because the

market is flocked with new and shinning equipment. Though, you can consider

searching for welding

equipment china for new and used robotic welding equipment.

Intelligent and Communication

In the case of the robotic welding system,

the robot controllers, system controllers for parts movement, human-machine

interface and environmental communication is very vital. Depending on the

system you are about to choose, you can expect the data acquisition to vary

greatly from one system to the other.

The Features of Robotic Welding Equipment

It’s very important to understand the

features of the machine you want to settle for and to be sure that the machine

will offer you the exact functionality you need. What will determine the types

of consumables and metal filler and wire feeding is your applications.

The peripherals

This is any other piece of equipment that

may be needed for additional functionality. The peripheral is integrated into

the robotic welding systems. If you want increased performance and setup,

choose the right kind of peripherals. Some of the most important peripherals to

consider include the Nozzle cleaning station, anti-spatter sprayers, arm mount,

wire cutters, and clutch.

Consumables

It’s also important to consider the

consumables including the nozzles, liners, contact tips, and retaining heads.

Depending on your application, you may have to choose different nozzles and

contact tips.

When shopping for quality welding equipment, you should have

all the above factors in your head. This will ensure you have robotic welding equipment that

will reduce your overall cost and improve the quality of your products.